How an ERP system can help improve Manufacturing performance?

AT A GLANCE

- Installation and modernization of ERP software comes at a high cost for manufacturing companies, and they are rightfully looking for ways to maximize their manufacturing performance from these software investments.

- Manufacturers must embrace the comprehensive ERP model and let their production line and their vendors work in tandem with the software to streamline processes.

- ERP systems are no longer a part of the business backend- newer tools and applications like Cloud, Internet of Things (IoT), and Machine Learning are changing ERP systems’ face, affecting the overall ROI of technology spend.

The implications and benefits of using a comprehensive tool like ERP are well measured in advance by large and small/ medium scale manufacturing organizations. However, there are still ways with which ERP systems can be used to better the overall operational efficiency in manufacturing, streamline existing processes, and improve the production line. These ways with which a solution like ERP can become the catalyst in generating ROI are usually the difference-makers for the manufacturing sector.

Mid-size businesses’ adoption of ERP software will grow at a CAGR of 7.9% from 2014 to 2020.– ALLIEDMARKETRESEARCH.COM

As the investments in ERP keep pouring in, manufacturers find themselves looking to adapt and manipulate their current practices to reap the maximum benefits from these investments above. Let us look at these practices that will improve ROI with ERP in the manufacturing industry. But first, let us learn how the ROI is calculated when it comes to manufacturing ERP.

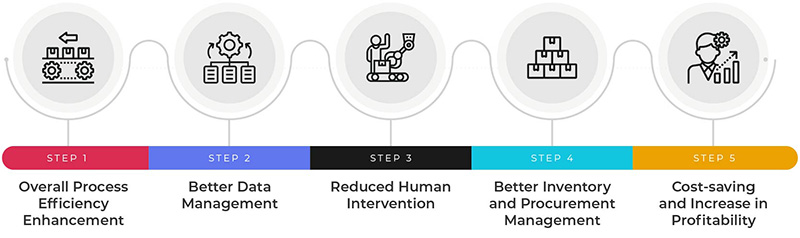

FIGURE 1:Factors that Decide the ROI of Manufacturing ERP

Calculating the ROI for ERP Manufacturing- A Comprehensive Look at the Benefits of Installing the ERP System

Every organization has specific short and long term goals in mind while installing an ERP system. So, while the ROI might be a relative concept for every manufacturer, certain common areas can help you decide as to exactly how beneficial can your ERP system be for your company:

- Does the ERP system help you in streamlining the processes and improving overall production line efficiency?

- Does it minimize human intervention and the cost spent on intensive labor for data management and analytics?

- Does it help you in managing your purchases, procurements, and inventory better?

- Does it help you get real-time visibility across the production line for improved communication and faster response time?

- What other tangible benefits mainly in terms of cost savings and profit gains can you see after installing the ERP system?

Once you get answers to these questions, you can calculate the ROI for your ERP.

The Road to Better Manufacturing ROI: Improving Manufacturing Performance with ERP

01.Efficient Machine-to-Machine and Machine-to-Human Interaction

In the times of Cloud dominated software practices, everything is virtually connected. Manufacturers have a chance of enhancing their ecosystem where real-time connectivity between the workforce and machines is established efficiently. This will add transparency to the entire production line from the top floor to the shop floor; it will also help the skill base use smart manufacturing techniques to save both time and effort. Application of ERP software to adopt smart manufacturing techniques will help manufacturers avoid production delays, track material and equipment with better efficiency, and move faster. All of this will result in more significant revenue generation.

FIGURE 2:ERP in the Manufacturing Industry

02.Better Management of Inventory

Large-scale manufacturers can afford to hire a larger workforce to manage their inventories. Small and mid-scale businesses often suffer a loss due to glitches in inventory management and its usage. Even larger companies are looking for a centralized network that can keep track of all the raw material, incomings, outgoings, and maintenance schedules for their inventories. This is where a modernized, sturdy ERP system succeeds where older, legacy platforms fail. It allows companies to get real-time data on their personnel and material in the inventory, allowing them to better plan their management well ahead in time. Any manufacturing company- large or small- will vouch that a well-managed inventory is a must to avoid stock-outs and other related production delays. So a robust ERP system will help in improving ROI by assisting manufacturers to improve their inventory management.

03.Forming a Competent Skill Base

No advanced software or tool could provide a manufacturer with better ROI if their workforce is not fully acquainted and expert in using the said software or tool. Well, the ERP system is no exception to this rule. Especially with the modernization of many of the ERP systems and its integration with cutting-edge applications like Internet of Things (IoT), Machine Learning, Advanced Analytics, and Artificial Intelligence, it has become highly imperative for manufacturing companies to train their skill base in expertly using the ERP system to its fullest capability. This will not only ensure lesser glitches but also prove to be beneficial in long term profit gains.

These positive changes in your manufacturing ecosystem will not only help you gain maximum benefit from your ERP system, but it will also solidify your work standards and technical competencies in the long run.

Key Takeaways:

- Modernization of ERP systems need not necessarily mean a costly affair for manufacturers if they utilize smart manufacturing techniques to improve their ERP ROI.

- Large and small and medium-scale manufacturers need to look at ERP software as an integral part of their production line and get their workforce well-acquainted with all the details for a better profit model.

Take Our Free Assessment to Get Started With Digital Transformation

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness